Introduction

In today’s competitive manufacturing and supply chain landscape, product labeling and packaging play an essential role not only in branding and customer communication but also in ensuring operational efficiency, compliance, and traceability. With the rise of Industry 4.0, the integration of barcode and QR code scanning systems has revolutionized how businesses track and trace products throughout the production lifecycle — from raw material to the end customer.

This document explores the complete workflow and importance of product labeling and packaging, followed by how traceability is achieved through barcode and QR code scanning systems, ensuring better quality control, inventory accuracy, and supply chain transparency.

1. Product Labeling: Function and Design

1.1 Purpose of Product Labeling

Product labels are more than just tags; they provide crucial information regarding:

- Product identity (name, SKU, batch number)

- Regulatory compliance (e.g., CE, RoHS, FSSAI, FDA labeling standards)

- Ingredients/material composition

- Warnings or handling instructions

- Tracking information (e.g., barcode or QR code)

1.2 Components of a Label

A well-designed product label includes:

- Brand logo and design

- Product name and variant

- Production/expiry date

- Serial number or batch number

- Barcode/QR code

- Certifications or regulatory marks

1.3 Label Printing Technologies

Common technologies used include:

- Thermal printers: For logistics and industrial use

- Inkjet/laser printers: For high-resolution, color labels

- RFID-integrated labels: For enhanced tracking

2. Product Packaging: Safety and Brand Communication

2.1 Importance of Packaging

Packaging ensures:

- Physical protection during transit and storage

- Preservation of product quality

- Information dissemination

- Brand communication and consumer appeal

2.2 Types of Packaging

- Primary packaging: Direct contact (e.g., bottle, pouch)

- Secondary packaging: Grouping (e.g., boxes, cartons)

- Tertiary packaging: Bulk handling (e.g., pallets, crates)

2.3 Smart Packaging Integration

Modern packaging integrates:

- QR codes for product info and marketing

- Tamper-evident seals

- Near-field communication (NFC) for authentication

3. Introduction to Barcode and QR Code Systems

3.1 What is a Barcode?

A barcode is a machine-readable code in the form of numbers and a pattern of parallel lines. It typically encodes a product ID, batch, or SKU for fast lookup in a database.

3.2 What is a QR Code?

A QR (Quick Response) code is a 2D barcode that can store more complex data, including URLs, documents, product specifications, and traceability logs.

3.3 Barcode vs. QR Code

| Feature | Barcode | QR Code |

|---|---|---|

| Format | 1D (linear) | 2D (matrix) |

| Data capacity | Low | High |

| Space requirement | More | Less |

| Readability | Line-of-sight | 360° angle |

| Usage | Inventory/SKU | Marketing, traceability |

4. Traceability in Production: Importance and Challenges

4.1 What is Traceability?

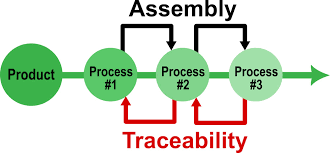

Traceability refers to the ability to track every stage of the production and supply chain — from raw materials to the finished product delivered to customers.

4.2 Why is Traceability Important?

- Quality control and recall management

- Compliance with regulatory standards (e.g., ISO, FDA)

- Counterfeit prevention

- Supply chain transparency

- Customer trust and product authentication

4.3 Common Challenges

- Manual entry errors

- Lack of standardization

- Poor integration between departments

- Inconsistent barcode formats

5. Integration of Barcode/QR Code Systems in Production

5.1 Barcode Generation and Printing

- Batch-wise or unit-wise codes generated via ERP or production software

- Printed using label printers integrated into production lines

- Each unit/package receives a unique identifier

5.2 Scanning Points Across Production

- Raw Material Entry:

- Incoming materials are scanned and recorded

- Ensures that only verified materials are used

- Production Stages:

- Barcodes scanned at each stage (cutting, assembly, testing)

- Real-time progress tracking

- Packaging:

- Final product is scanned before packaging

- Labels generated based on unique item IDs

- Warehouse and Dispatch:

- Scanning during palletization and dispatch ensures correct routing

- QR codes may link to product manuals or warranty registration

- Post-Sales Tracking:

- Retailers and consumers can scan QR codes to verify authenticity

- Companies can gather customer usage data and feedback

6. Software and Hardware Ecosystem

6.1 Barcode/QR Code Software

- ERP Systems (e.g., SAP, Oracle, Odoo)

- MES (Manufacturing Execution System)

- Label Design Tools (e.g., Bartender, ZebraDesigner)

- Inventory/Traceability Modules

6.2 Barcode/QR Code Hardware

- Label printers (Zebra, TSC, Sato)

- Scanners (Honeywell, Datalogic, Symbol)

- Mobile devices/tablets with scanning apps

- RFID/QR hybrid systems for high-volume environments

7. Real-Life Example: Electronics Manufacturer

Let’s consider a smartphone manufacturing plant:

- Each phone unit has a unique QR code

- During PCB assembly, the code is scanned and linked to a specific motherboard

- Testing logs are linked to the same code

- At packaging, the code embeds warranty info and guides for customers

- Retailers scan the code to validate stock

- If a batch shows defects, the specific serial numbers are recalled, not the entire production lot

8. Benefits of Barcode and QR Code Traceability

8.1 For Manufacturers

- Reduced waste through batch-level recall

- Efficient inventory tracking

- Better compliance audits

- Faster production line diagnostics

8.2 For Distributors

- Smarter stock management

- Real-time shipment tracking

- Verification of authorized resellers

8.3 For Consumers

- Authentication of genuine products

- Instant access to product manuals, support links, and warranty

- Ability to participate in loyalty programs via QR scan

9. Advanced Concepts

9.1 Serialization

Serialization involves assigning a unique serial number to each item. This is especially used in pharmaceuticals and electronics to ensure unit-level traceability.

9.2 Blockchain + QR Code

Some companies integrate QR code scans with blockchain, ensuring immutable records of each product’s history — especially useful in food and luxury goods.

9.3 AI and Image Recognition

Some newer systems use AI-based visual recognition to validate labels/barcodes even if partially damaged, enhancing reliability.

10. Regulatory and Global Standards

- GS1 Standards for universal barcoding

- FDA Drug Supply Chain Security Act (DSCSA)

- EU Medical Device Regulation (MDR)

- ISO 9001/22005 for traceability systems