Without barcodes, traceability is impossible. Barcodes identify products, assets, and shipments in a supply chain. Here’s how barcodes contribute to traceability:

At SavTech, we believe barcodes are the foundation of modern traceability. In today’s dynamic supply chain environment, accurate product tracking is not just a benefit—it’s a necessity. Barcodes serve as the digital fingerprints of products, assets, and shipments, ensuring complete visibility from origin to destination.

Here’s how SavTech’s barcode technology enables end-to-end traceability:

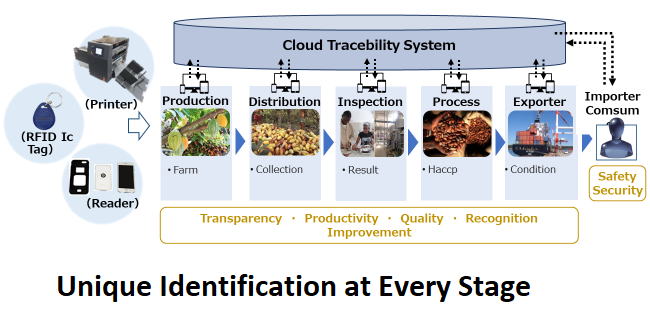

1. Unique Identification at Every Stage

Every item within your supply chain is assigned a unique barcode using SavTech’s labeling solutions. This barcode can encode vital details such as product type, batch or lot number, and expiration date. This level of granularity allows businesses to track individual units as they move across the supply chain—ensuring transparency and accountability.

2. Real-Time Data Capture

SavTech’s barcode scanning technology enables real-time updates on product movement, storage, and status. At each checkpoint—whether it’s manufacturing, warehousing, or dispatch—scanners capture and transmit accurate data into your central system, giving your operations team the visibility they need.

3. High Accuracy and Operational Efficiency

Manual data entry is error-prone and time-consuming. SavTech’s barcode systems eliminate these inefficiencies. With instantaneous scanning, inventory updates, shipment verifications, and item-level tracking become highly accurate and efficient—key factors in maintaining robust traceability.

4. Seamless Integration with Your Systems

Whether you’re using an ERP, WMS, or custom inventory solution, SavTech’s barcode software integrates smoothly. Our solutions are designed to sync effortlessly with enterprise systems, ensuring consistent and accurate data across your organization’s digital ecosystem.

5. Compliance with Industry Standards

In regulated industries such as pharmaceuticals, food & beverage, and automotive, traceability is not optional—it’s mandatory. SavTech helps businesses comply with traceability standards and regulatory frameworks by ensuring every item is traceable through its lifecycle, enabling faster recalls and audit readiness.

6. Counterfeit Prevention and Product Authenticity

Barcodes act as a first line of defense against counterfeiting. By continuously tracking each item’s movement against expected shipment routes and ASN (Advanced Shipment Notification), SavTech’s systems can instantly detect duplicate or fraudulent entries, safeguarding product integrity.

7. Rapid Recall and Quality Control

In the event of a product recall or defect, SavTech’s traceability platform can instantly identify affected batches, pinpoint their location, and initiate recall workflows. This minimizes consumer risk and helps protect your brand’s reputation.

Advantages of Barcode Scanning in Inventory Traceability

In today’s fast-moving supply chain environment, efficient inventory traceability isn’t just beneficial—it’s essential. A robust traceability system involves tracking products by SKU, batch number, or serial number, enabling accurate and real-time visibility across the warehouse and beyond.

When hundreds of product batches are received, moved, or shipped daily, relying on paper logs or spreadsheets quickly becomes unmanageable. That’s where barcode scanning transforms the process—by dramatically improving speed, accuracy, and traceability.

Let’s explore the key advantages of using barcode scanning and mobile technology for a modern, digital inventory traceability system:

✅ 1. Time-Saving Automation

Manual tracking is slow, tedious, and prone to delay. Barcode scanning automates data capture, reducing the time spent on inventory checks, product movements, and data lookups. Tasks that once took hours can now be completed in seconds, freeing your team to focus on higher-value activities.

✅ 2. Enhanced Accuracy and Error Prevention

Manual entry is a frequent source of costly errors—especially when dealing with long alphanumeric batch or serial numbers. Barcode scanning eliminates these mistakes by capturing data instantly and precisely, ensuring that every movement is recorded correctly and securely.

✅ 3. Real-Time Inventory Visibility

With barcode-enabled mobile apps, warehouse teams can access live inventory data anytime, anywhere. From identifying a product’s location to tracking its journey through the supply chain, barcode technology provides instant insights into stock levels, expiry dates, batch information, and more.

✅ 4. Increased Customer Confidence

Consumers and partners increasingly demand transparency. A digital barcode traceability system helps you provide that—allowing quick responses to customer queries, faster recalls if needed, and a more trustworthy supply chain. This builds customer loyalty and positions your brand as reliable and proactive.

✅ 5. Mobile Flexibility with Field-Friendly Tools

All inventory processes don’t happen at a desk. That’s why mobile scanning technology—like the SavTech Warehouse App—enables your team to work from the floor, loading dock, or delivery point, ensuring accuracy at the source and reducing back-office delays.

✅ 6. Scalability and Integration

Barcode scanning is easily scalable and integrates smoothly with ERP, WMS, or inventory systems. Whether you’re managing a single warehouse or a global distribution network, barcode systems grow with your operations, ensuring consistency across every touchpoint.

Conclusion

With SavTech’s barcode-driven traceability solutions, businesses gain control, visibility, and trust across their entire supply chain. Whether you’re tracking raw materials, finished goods, or assets, our systems ensure you meet compliance standards, prevent errors, and respond swiftly to challenges.

Barcode traceability isn’t just a technology—it’s a strategic advantage. Let SavTech help you build it.