Inventory control, often referred to as stock control, is the strategic process of overseeing and managing a company’s inventory—covering everything from raw materials to finished products—across warehouses and other storage points. It involves a comprehensive set of procedures and tools that ensure goods are available in the right quantity, in the right condition, and at the right time to fulfil customer demands and optimize business profitability.

An effective inventory control system empowers companies to streamline operations, reduce waste, and enhance customer satisfaction through better stock visibility and accountability.

Core Activities of Inventory Control

To maintain a robust inventory control process, organizations typically follow these critical activities:

- Receiving, organizing, and relocating goods within the warehouse

- Strategic placement of stock for optimized picking and restocking

- Tracking inventory in real-time, including location and quantity

- Maintaining detailed product records, including item history and movement

- Monitoring inventory condition to prevent spoilage, obsolescence, or damage

- Order fulfillment using available stock efficiently

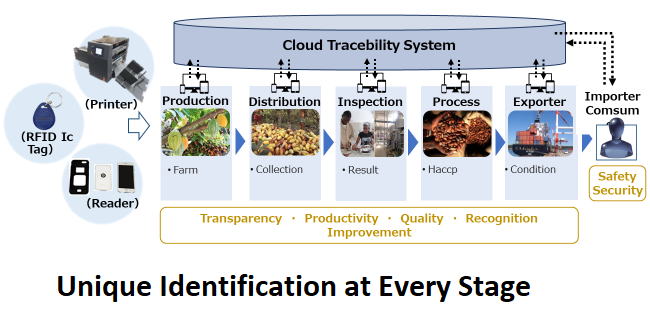

- Barcode and RFID integration for automated tracking

- Reorder reporting to prevent stockouts or overstocking

Inventory Control vs. Inventory Management

Although these terms are often used interchangeably, they refer to different aspects of the supply chain:

| Aspect | Inventory Control | Inventory Management |

|---|---|---|

| Scope | Current inventory within warehouses | Flow of goods across the full supply chain |

| Objective | Maintain accurate stock levels and quality | Ensure timely availability of materials and products |

| Focus Areas | Item locations, condition, and counts | Forecasting demand, replenishment, and logistics |

| Key Activities | Stock monitoring, storage, inspection | Reordering, distribution planning, supply chain coordination |

Types of Inventory Control Systems

Inventory control systems leverage technology to monitor and optimize stock levels and movements. The two main types are:

1. Periodic Inventory Control System

This system relies on scheduled physical counts—typically monthly, quarterly, or annually. Inventory data is updated only after each count.

- Advantages: Simple to implement; minimal tech requirements

- Disadvantages: Time-consuming for large inventories; prone to errors

- Ideal For: Small-scale businesses with manageable inventory volumes

2. Perpetual Inventory Control System

This modern system uses real-time tracking through barcodes or RFID, with continuous data updates stored in a centralized inventory database.

- Advantages: Offers real-time visibility and accuracy; enables data-driven decisions

- Disadvantages: Higher setup and maintenance costs; may not capture shrinkage or damage automatically

- Ideal For: Large enterprises and multi-location businesses with high-volume inventory

Inventory Control Techniques

Inventory control techniques are essential for optimizing stock levels, minimizing waste, and ensuring smooth operations. Key methods include ABC Analysis, which prioritizes items based on value and usage; FIFO (First In, First Out) and LIFO (Last In, First Out), which determine the order of stock usage; Batch Tracking, which monitors goods by production lots for traceability; and Safety Stock, which provides a buffer against supply chain disruptions. By applying these strategies, businesses can improve accuracy, reduce costs, and enhance customer satisfaction through better inventory planning and control.

Applying proven inventory control methods is essential to maintaining operational efficiency. Below are some of the most effective techniques:

1. ABC Analysis

This method categorizes inventory into three groups based on value and usage frequency:

- A-items: High-value, low-frequency items—require strict control

- B-items: Moderate value and frequency—require balanced oversight

- C-items: Low-value, high-frequency items—require minimal controls

This prioritization helps businesses focus resources where they matter most.

2. FIFO & LIFO

- First In, First Out (FIFO): Assumes that the oldest stock is used or sold first—ideal for perishable goods and ensuring freshness.

- Last In, First Out (LIFO): Assumes the most recently received stock is used first—more suited for non-perishable goods in environments with rising prices.

3. Batch Tracking

This technique monitors inventory by batch numbers or production lots. It enhances traceability, simplifies recalls, and ensures consistent quality control—especially useful in pharmaceuticals, food, and electronics.

4. Safety Stock

Safety stock refers to maintaining extra inventory to cushion against unpredictable demand or supply disruptions. It acts as a buffer to reduce the risk of stockouts and ensure service continuity.

Achieve Operational Excellence

Embracing advanced inventory control techniques is a key step toward achieving operational excellence. By integrating digital solutions, businesses can enhance agility, reduce losses, and create a culture of continuous improvement. Whether you’re optimizing a single warehouse or managing global operations, effective inventory control is the foundation of a responsive and resilient supply chain.

Explore how our intelligent inventory solutions can empower your business today.

Let me know if you’d like this customized further for a brochure, website, or presentation.

One response to “What is Inventory Control?”

[…] What is a Barcode Inventory System? […]